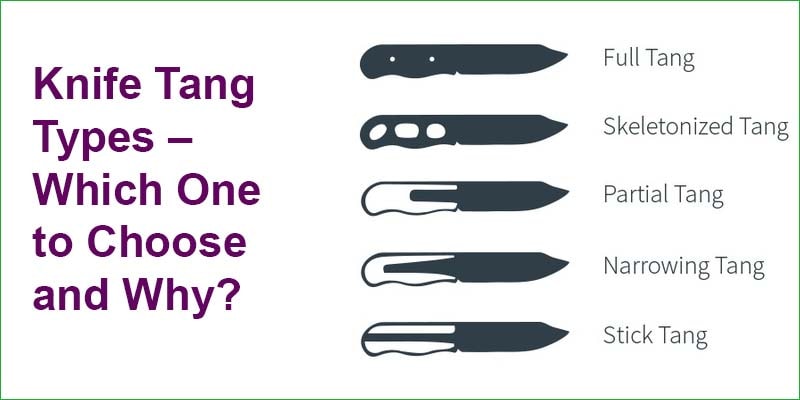

A tang is one of the most integral characteristics of a fixed blade knife. Also known as a sheath knife these blades don’t fold down as an EDC knife or folding knife does. I’m going to skip the obligatory popular 1960s orange powdered drink joke here and get straight to it.

In the simplest of terms, the tang of a knife is the bit that extends below the blade and provides the basic structure for the handle. It is effectively the foundation on which the knife is built. Arguably the most important characteristic imparted to the knife by the tang is the overall balance. A superior knife will have its center balance point in the wielder’s hand, making precise control of the blade nearly effortless. If the balance is too far toward the tip or the pommel, then the knife may become unwieldy and dangerous.

To choose a tang you must first understand the terminology and that it is possible to bridge several categories simultaneously; you, therefore, have the possibility of having a hidden, encapsulated, stick tang, and so on.

You May Like: Best Fixed Blade Knives Under $200

Full Tang Knife

The first major tang category is the full tang. This features metal running the entire length of the handle and culminates with a pommel or butt at the base of the knife usually to secure the handle to the blade. A full tang is overall the strongest construction due to the sheer amount of material built into the handle. This will produce a knife that is unlikely to bend or break during its service duties. Full tang design is very common in tactical knives, survival knives, combat knives, bowie knives, and some other types of knives that are commonly used for heavy-duty chores.

What’s the drawback of all this strength? The weight; once again due to a large amount of metal used in its construction. There are two sub-categories within this group and some confusion between the two. A through tang is any tang that extends completely through the grip, whereas, with a slab tang, the metal tang is visible on the front, back, and base of the handle. Many people may incorrectly infer that a full tang is always a slab tang.

I have some review articles in this blog where I recommend the best full tang knives in the world that you can check out if you want.

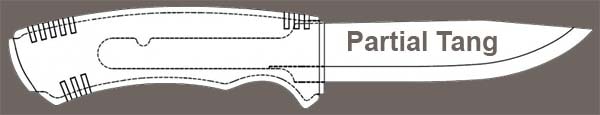

Partial Tang Knife

The second major tang category is the partial tang. If it’s not a full tang, it’s a partial tang. This simply describes a tang that extends only partially into the handle. This tang is referred to by many other names, including but not limited to: half tang, stub tang, three-quarter tang, etc.

In the past having a partial tang would be a major drawback to a fixed blade knife due to the decreased overall strength and habit of the handle becoming separated from the blade. However, modern manufacturing techniques and better adhesives have led to a large number of high-performing partial tang knives. The decreased metal in these tangs yield lighter knives and handles making the knife less of an anchor.

This also gives the opportunity to use a wider array of materials in the construction of the grip – materials that don’t split well or are difficult to work with, like horns and antlers. Depending on the weight and material used for the handle, the center of balance will typically be shifted closer to the blade. When stressed to the limit, let’s face it, partial tangs will never be as strong as full tangs – a partial tang will fail first.

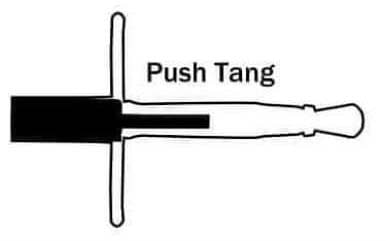

Push Tang Knife

The Push tang is, as the name suggests when the tang is pushed into the handle and then fixed to the handle and secured with an adhesive. These knives can be both partial or full (through) tang.

These tangs generally cost less than others and are commonly used in mass production. Historically they have been criticized as weak, but with modern manufacturing techniques and industrial epoxies, the shortcomings are less noticeable.

Encapsulated Tang Knife

With an encapsulated tang, the handle is molded around the tang and fastened in place rather than pushed. The benefits of this full tang knife are increased strength and precision – unlike push tangs, there’s no weak contact point between the handle and the tang.

Some Japanese kitchen knife makers produce their knives (the Yanagiba knives, Nakiri knives, and Santoku knives) with encapsulated tang designs. The drawback here is that the molding technique may limit the construction materials that can be used for the handle.

Hidden Tang Knife

A hidden tang describes any tang whose handle attachment can’t be seen externally. Many hidden tangs are also pushed tangs but this is not exclusive. There are several manufacturing techniques to achieve this: one is to use epoxy and push the tang into the handle. It is possible to create a “continuous” handle by drilling a hole through a solid material (like a stag) and securing it with a pommel or butt cap. Another common way is to rabbet the tang; splitting the handle material in half, making semi-circular holes in each half, and securing the two halves together again with epoxy, rivets, or friction (tightly woven cloth in the case of ancient samurai swords).

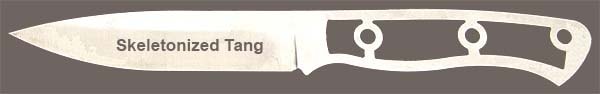

Skeletonized Tang Knife

A skeletonized tang refers to any tang that has portions that are missing or hollow. This technique retains the framework and reduces the overall weight with only a negligible decrease in performance. Many skeletonized tangs feature minimalist designs with cord-wrapped, molded handles, or no material at all, to retain the hollowed look.

The skeletonized tang is also popular among the blade design of chef knives like the Gyuto knives, Paring knives Steak knives, Deba knives, etc. Overall these tangs result in a striking look and good balance and are becoming a popular platform for many blades. Some hidden tangs are skeletonized just to save on weight. While this tang has some excellent benefits, it is still not as strong as a full (slab) style tang.

Stick Tang or Rat-tailed Tang Knife

The next tang is a stick tang or rat-tailed tang. The object here is to use as little metal as possible to secure the blade to the handle, which results in cheap, weak, breakable knives. These tangs are used in decorative pieces and are (at best) good for casual use only. Although they can technically be full (through) tang, these are to be avoided. The construction leaves 90° angles between the blade and the tang at the hilt, resulting in a weak area that can break if any strain is applied to it. These tangs, perhaps rightfully, have a reputation for being weak and easily breakable under strenuous use. Avoid these unless you’re looking for an inexpensive showpiece.

Tapered or Narrowing Tang Knife

The more robust cousin of the stick tang is the tapered or narrowing tang. Tapering from the blade to the tip of the tang has nixed the 90° angles and results in a stronger knife. The reduced material results in cost savings without completely compromising the strength. This creates a knife balance that’s tipped towards the blade with a good strength-to-weight ratio.

However, this is a more complicated tang design and manufacturing process, so it’s only utilized successfully by custom knifemakers and is rarely used in mass production. If you’re going to pay for a custom knife there may be better options.

Extended Tang Knife

The extended tang features a full tang that extends past the handle and protrudes out the back. This tang is popular amongst tactical knives, survival knives, and fighting knives for additional utility – like emergency hammering.

Many of these builds feature a lanyard hole for additional security. The additional metal may result in a heavy knife but retains a good overall balance. This style of tang may limit the type of handle material used in construction.

Integral Tang Knife

The final tang rounding out the list is the integral tang. Not to be confused with the integral locking mechanism common in many tactical pocket knife designs; this tang is as much of a work of art as it is a knife. This type of tang is milled from a single solid billet of steel; this results in a beautiful artistic work where every molecule of steel is in line, yielding a wood-like grain that runs throughout the knife. The tang bolsters, and the blade is all one solid continuous piece of metal. This gives the strongest possible knife construction; also probably the heaviest.

The other major problem with this manufacturing process is that using a single steel block for one knife is incredibly wasteful- about two-thirds of the block will be discarded. Due to the pure unadulterated inefficiency alone, this construction is rarely used. This also means – you guessed it – it’s massively expensive; it’s not uncommon for integral knives to run into the thousands. Like they say when buying art – you only need it if you need it. There are a few different sub-category terms that get used here; an integral knife does not include the pommel (no ifs and or butts) while a full integral does.

Conclusion

As a self-proclaimed survivalist, the tactical fixed blade knife that I personally use is an extended full-tang handle (Gerber StrongArm) for emergency hammering. Also, the extended tang part has a lanyard hole for the paracord. I enjoy the added utility of the extended tang with the good strength, weight, and balance of the tactical knife; and the paracord allows me to repurpose the handle if I need a few feet of rope in a pinch.

Every knife has different uses; the tangs that I’ve listed cover uses from artistic showpieces to staunch survival platforms and everything in between. Find the right tang for your individual needs and wants and get a feel for what you like. The ergonomics of the in-hand feel of a knife will be the ultimate deciding factor in any piece that earns a trusted place by your side.

Great article! Thanks for taking the time to put this together.